🧩 Fusion 360 Engineering & Design Portfolio

This portfolio showcases a selection of engineering and product design projects developed in Autodesk Fusion 360, focused on real-world manufacturability, structural integrity, and professional-grade visualization.

The work spans assistive technology, agricultural devices, robotics, musical equipment, and outdoor products, combining mechanical engineering principles with digital fabrication workflows.

🧠 Design Philosophy

My design approach prioritizes:

- Manufacturability-first engineering

- Modular and parametric design

- Structural durability for real-world use

- Clear separation of functional systems

- High-fidelity visualization for technical and commercial communication

Fusion 360 was used not only as a CAD tool, but as a complete product development environment, from concept to final render.

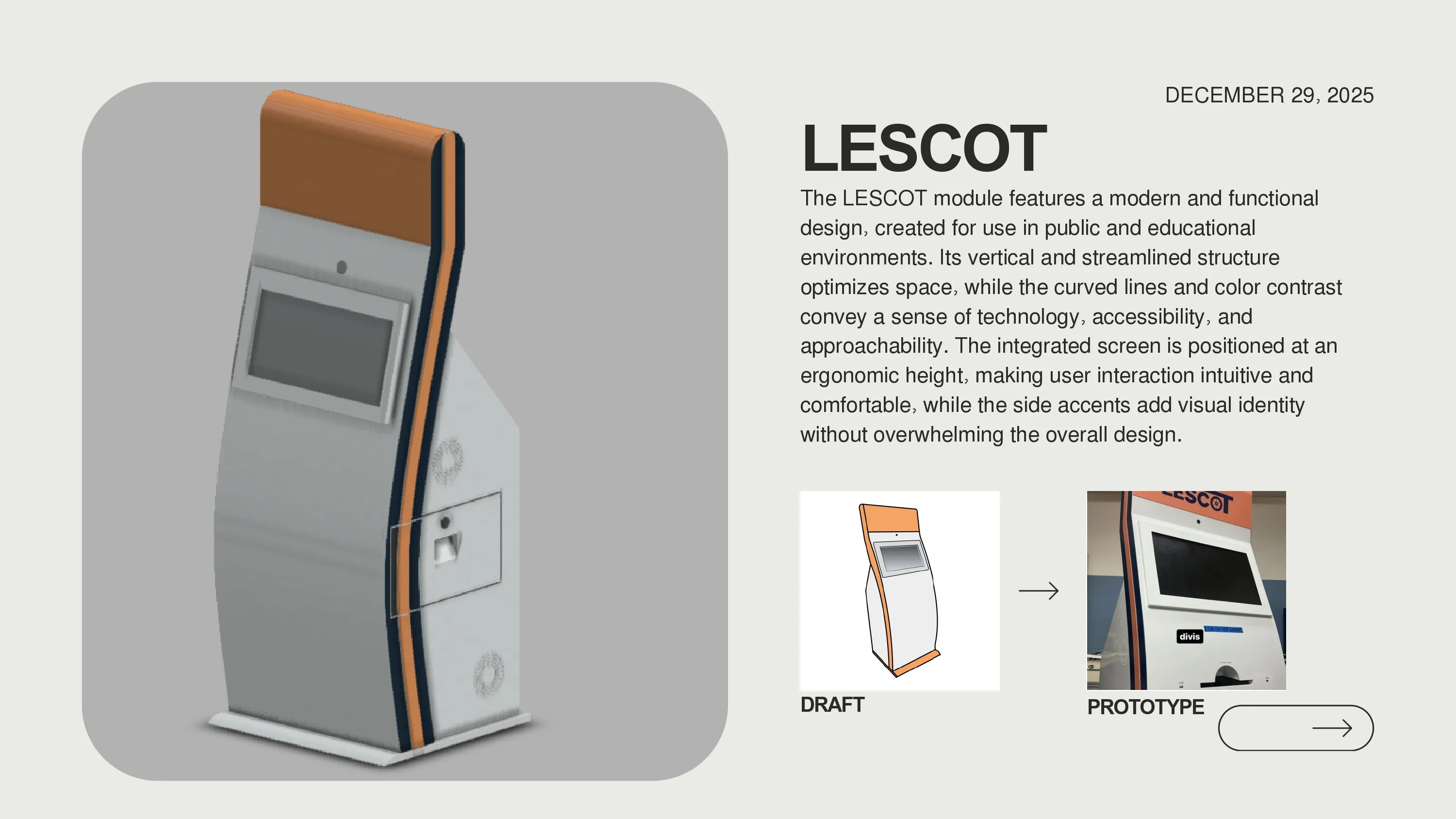

🤟 LESCOT Module (2023–2024)

The LESCOT module was designed as a public-facing assistive technology device for Costa Rican Sign Language (LESCO) translation.

Design Highlights

- Vertical, space-efficient structure

- Ergonomic screen placement for intuitive interaction

- Smooth curves and contrasting colors to convey accessibility and technology

- Designed for educational and public environments

Tools & Methods

- Fusion 360 parametric modeling

- Ergonomic layout optimization

- High-quality rendering for presentation and exhibitions

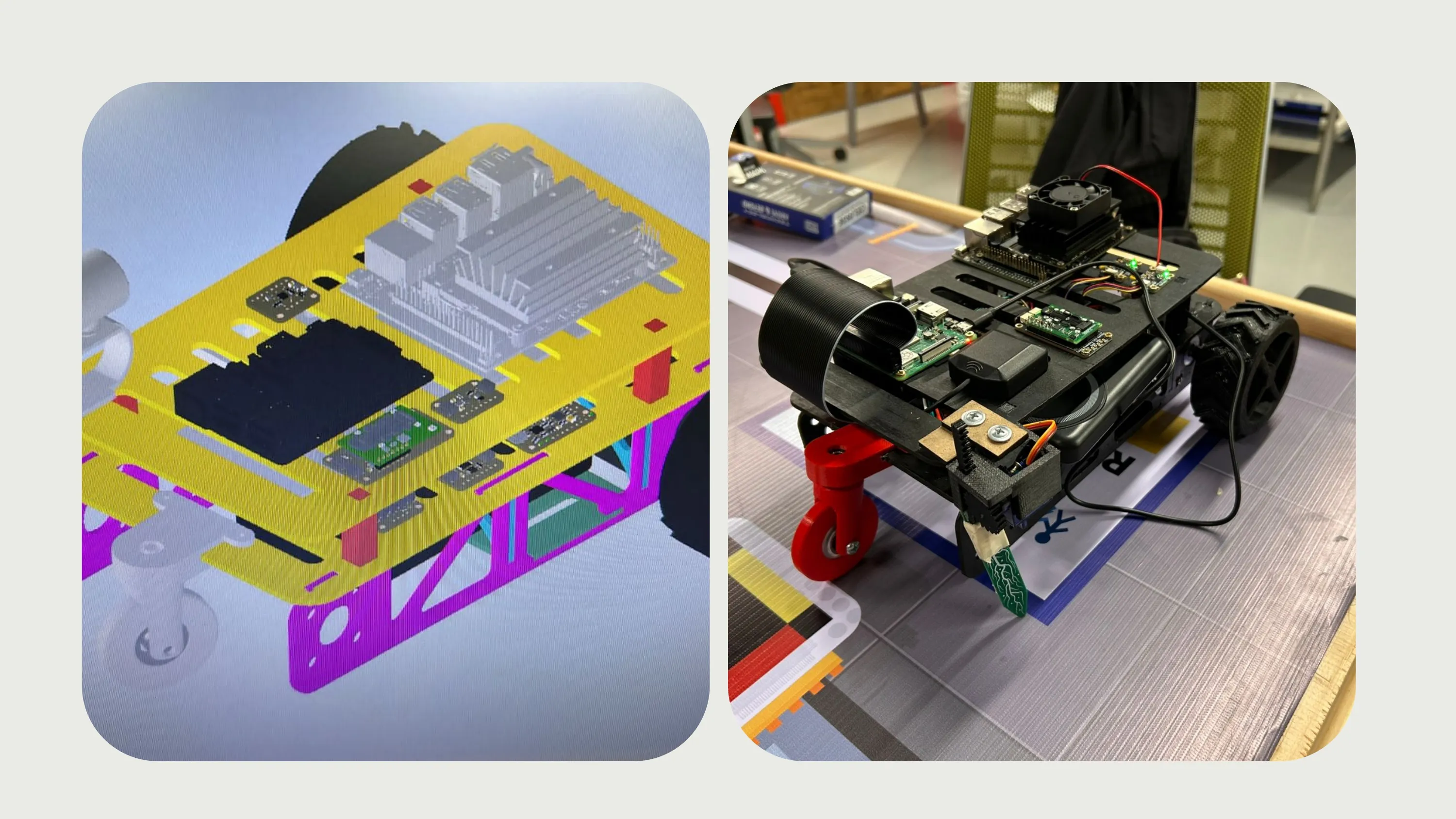

🤖 Agricultural Robot Chassis – Collaborative Project

This project involved the design and visualization of a mobile robot chassis, optimized for laser-cut fabrication.

Engineering Focus

- 2D parametric sketching for precise MDF assembly

- Dual-tier architecture separating power and control systems

- Integration planning for vision systems and high-performance processors

Collaboration

Developed as part of a three-person engineering team, focusing on mechanical precision and assembly efficiency.

Visualization

- Fusion 360 Rendering workspace

- Advanced material mapping

- HDR environmental lighting for realistic scale and context

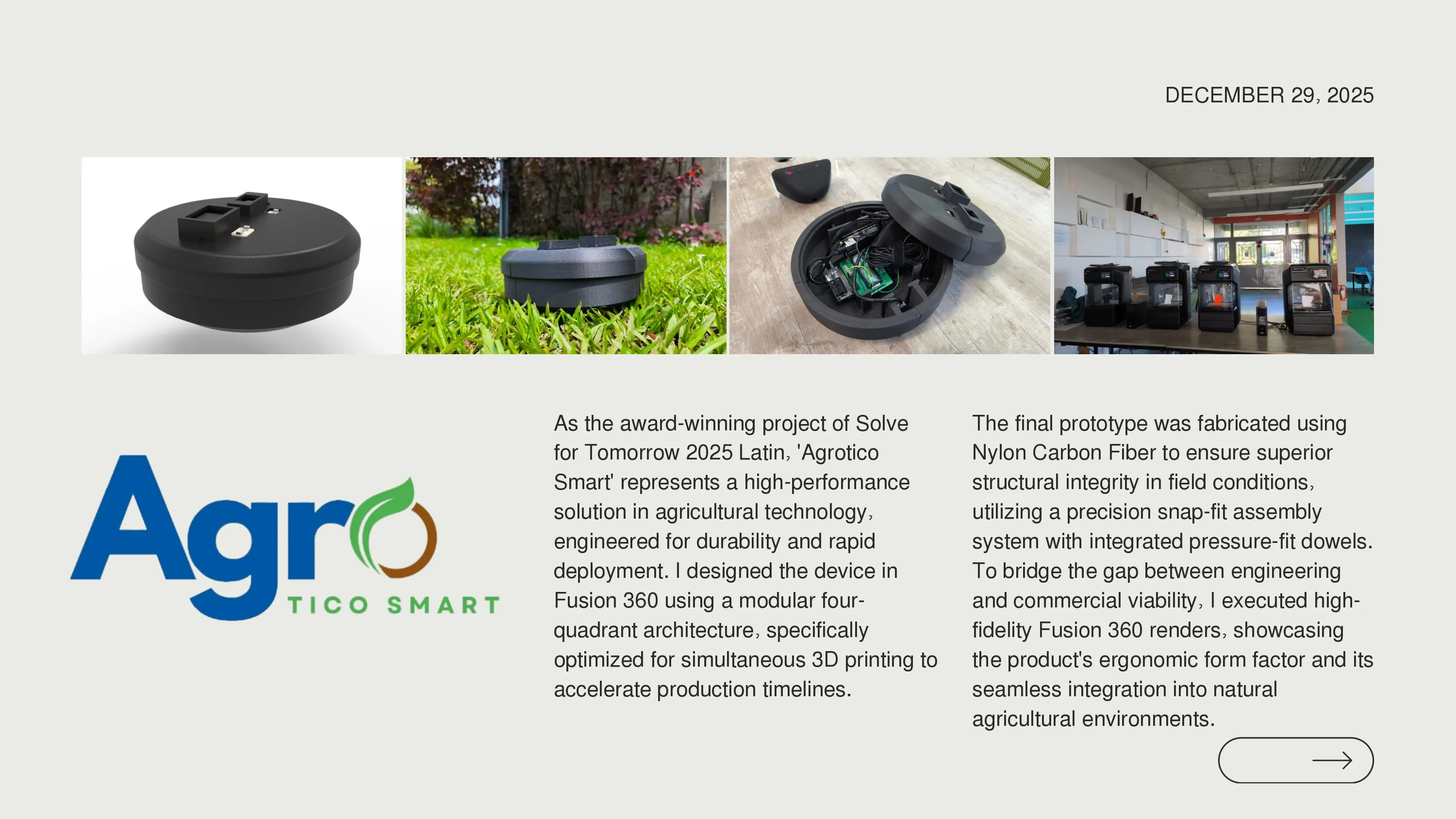

🌱 AgroTico Smart Device (Solve for Tomorrow 2025 – LATAM Winner)

As part of the award-winning AgroTico Smart project, I designed a field-deployable agricultural device engineered for durability and rapid production.

Key Design Features

- Modular four-quadrant architecture

- Optimized for simultaneous 3D printing

- Snap-fit assembly system with pressure-fit dowels

- Designed for outdoor agricultural environments

Materials & Fabrication

- Nylon Carbon Fiber for structural strength

- Modular design to reduce production time

- High-fidelity renders bridging engineering and commercialization

🏆 Samsung Solve for Tomorrow 2025 – Latin America Winner

🥁 Snare / Tenors Practice Pad (Personal Project)

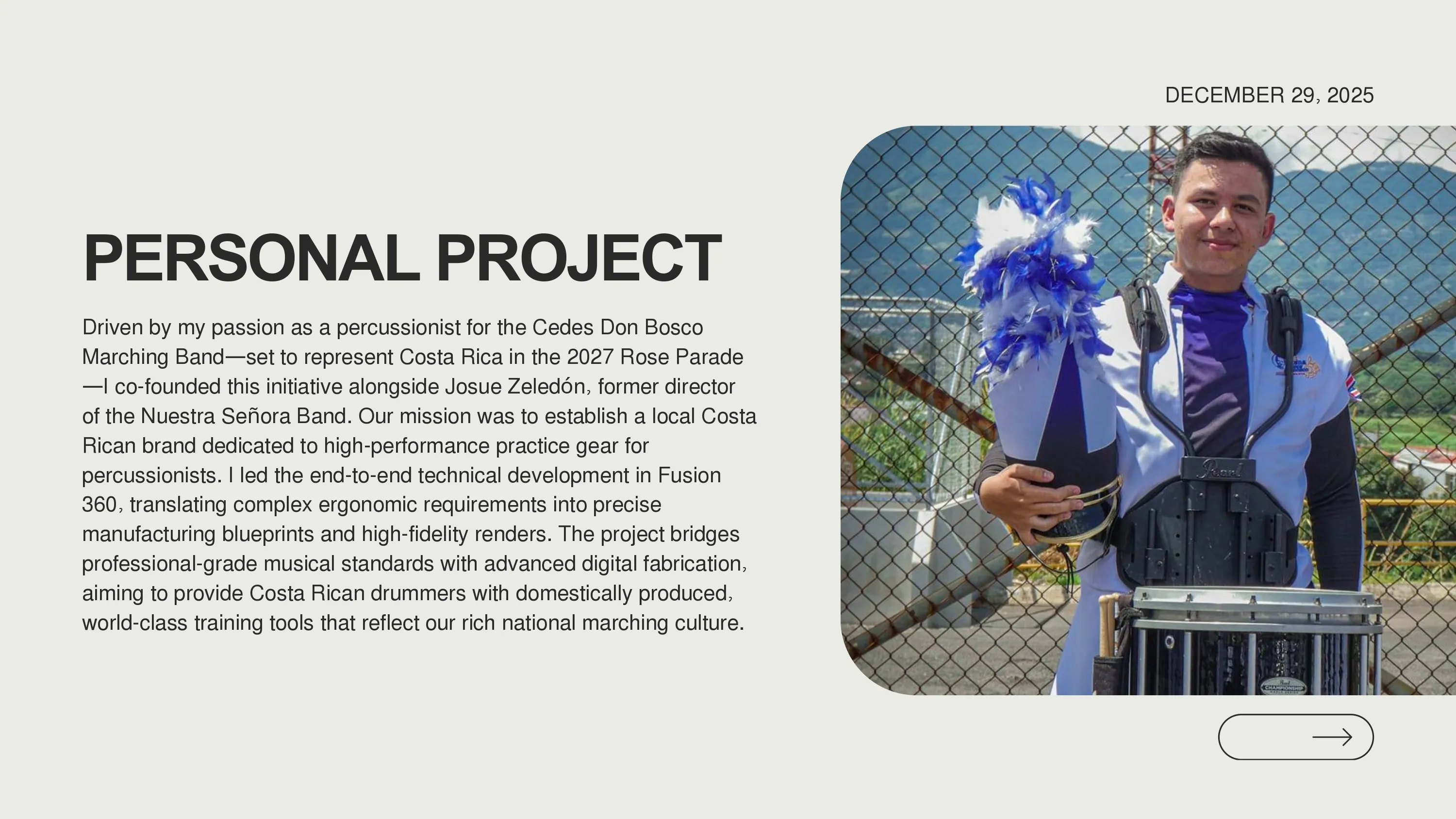

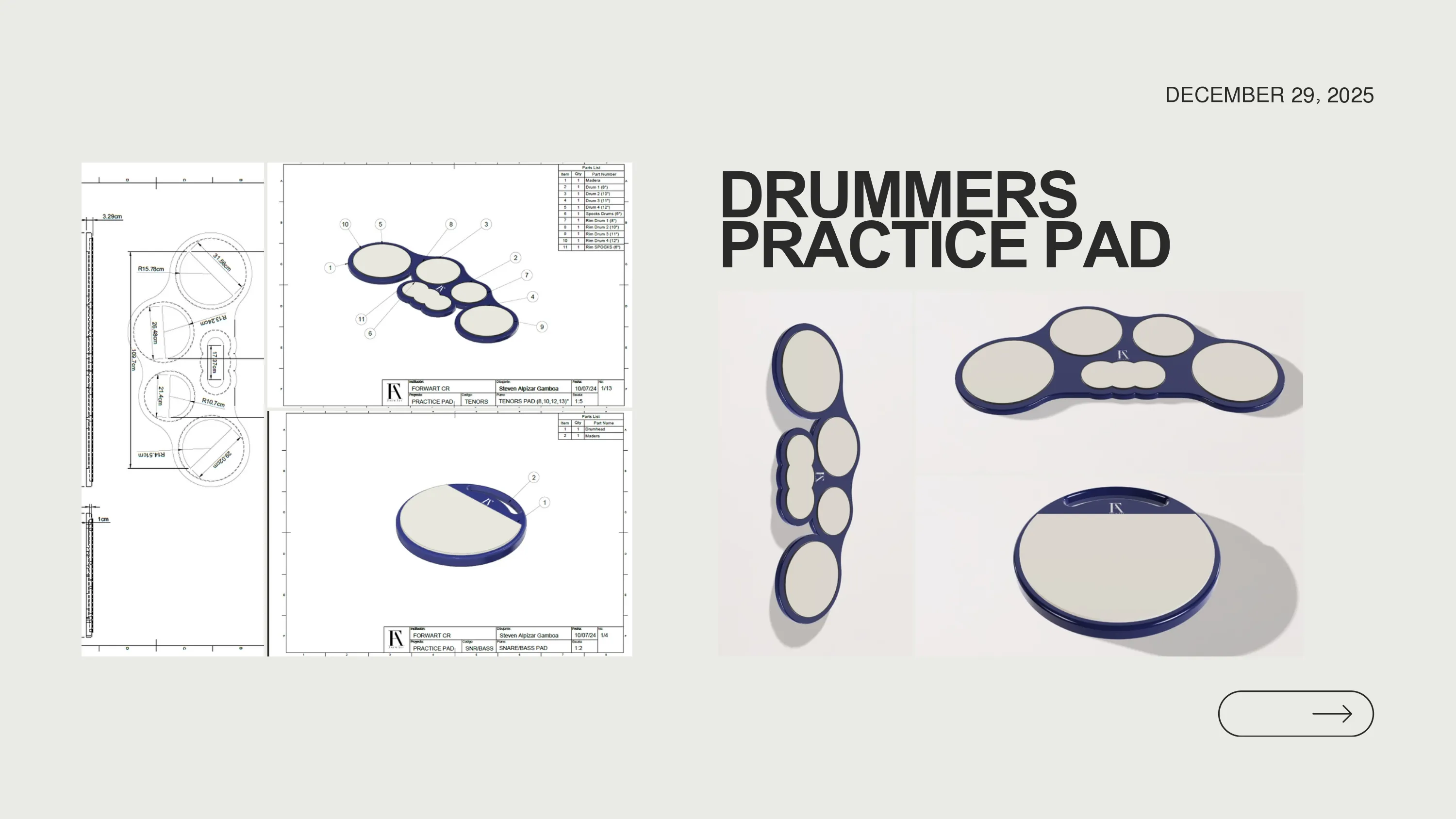

Driven by my experience as a percussionist in the CEDES Don Bosco Marching Band, I co-founded a project to develop professional-grade percussion practice equipment.

Design Objectives

- Ergonomic optimization for long practice sessions

- Professional musical standards

- Local manufacturing feasibility

Role

- End-to-end mechanical design in Fusion 360

- Manufacturing-ready blueprints

- Product visualization for branding and presentation

This project aims to establish a Costa Rican brand of high-performance percussion gear.

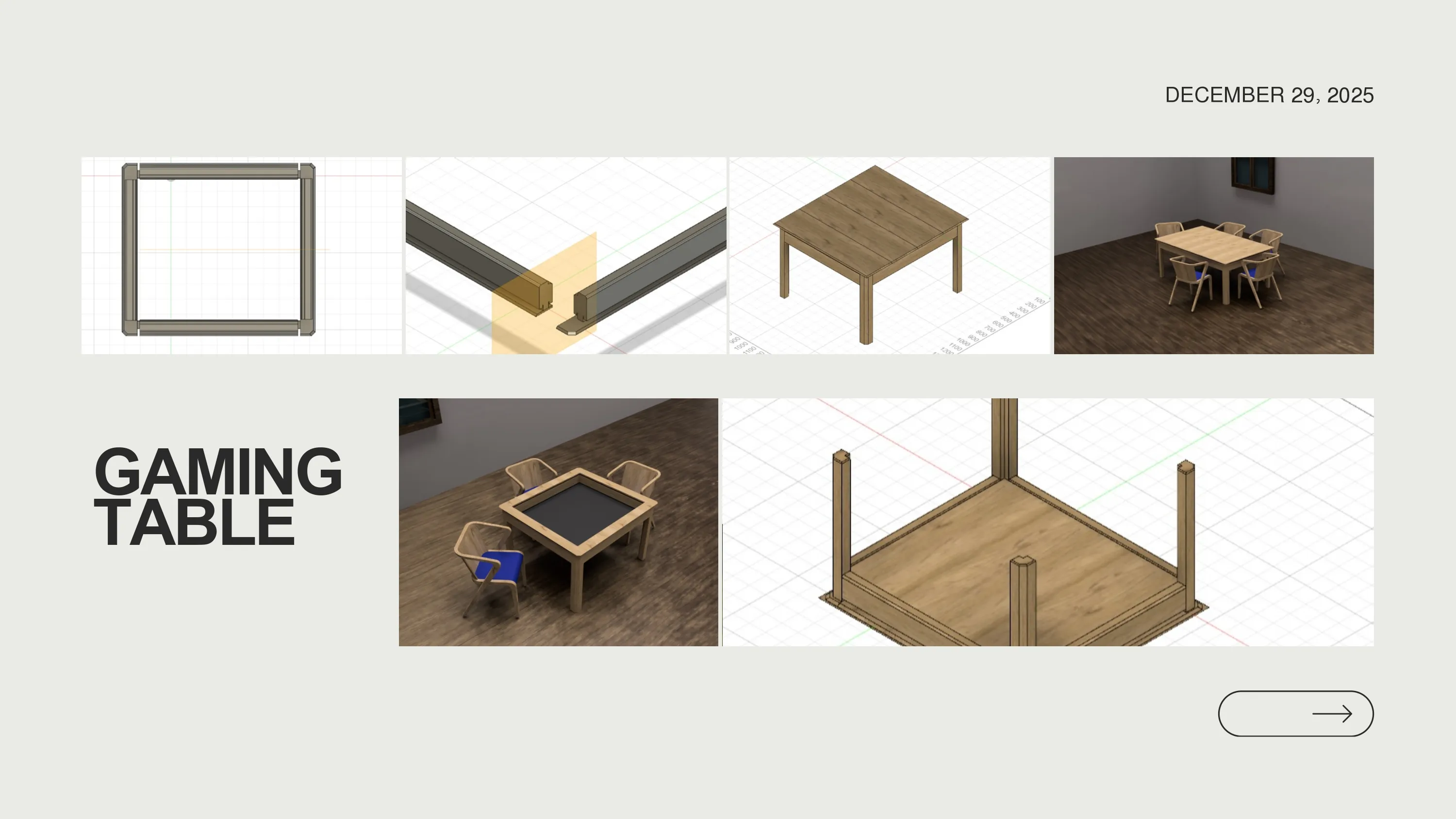

🎮 Gaming Table (Personal Project)

A custom-designed gaming table, focused on:

- Structural stability

- Cable management

- Ergonomic layout

- Clean industrial aesthetics

Designed entirely in Fusion 360 with emphasis on user comfort and modular assembly.

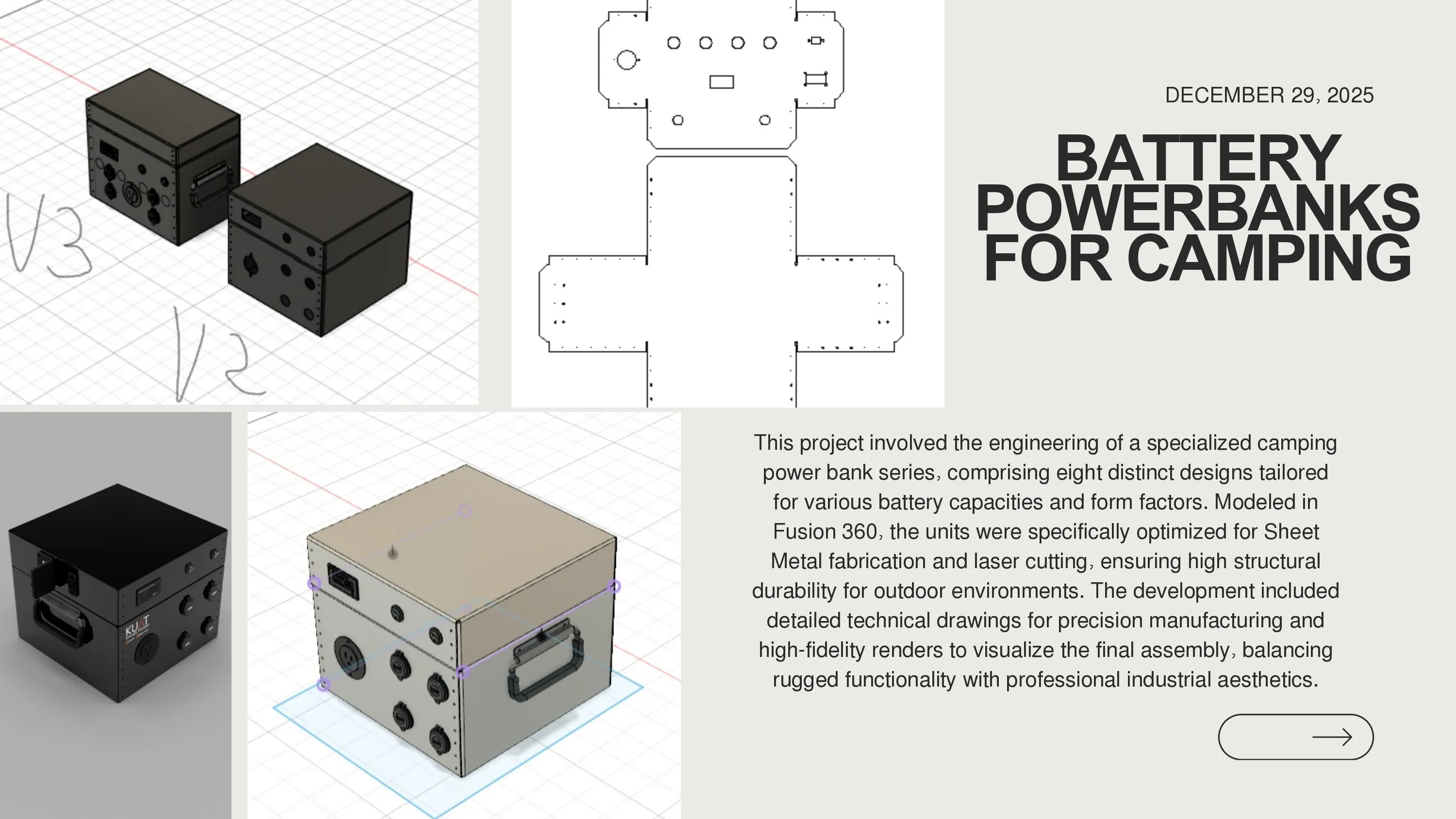

🔋 Camping Battery Power Banks (Laser Cutting Project)

This project involved the engineering of eight distinct camping power bank enclosures, each tailored for different battery capacities.

Engineering Focus

- Sheet metal design workflows

- Laser cutting optimization

- Rugged outdoor durability

- Precise technical drawings for fabrication

Output

- Manufacturing-ready files

- Professional-grade renders

- Modular enclosure system

🛠 Skills Demonstrated

Technical Skills

- Advanced Fusion 360 modeling

- Parametric and modular design

- Sheet metal and laser-cut fabrication

- 3D printing optimization

- Assembly and tolerance planning

- High-fidelity rendering and visualization

Professional Skills

- Design for manufacturability

- Cross-disciplinary collaboration

- Product presentation and documentation

- Engineering-to-market communication

🚀 Closing Statement

This portfolio reflects my ability to translate ideas into functional, manufacturable, and visually compelling products, using Fusion 360 as a core engineering tool across diverse industries.

Designed, engineered, and rendered by Steven Alpízar Gamboa.